-Interior cross hatching (cont...)

You certainly have extensive knowlodge and it is really interesting, you must have read every Meccano Magazine and retained all that information, brilliant.

Its little bits of information like this that puts perspective on the production.

You have certainly answered my questions

Thank you David

David,

Your USB stick has been posted yesterday.

I wish you a good reading

Jacques

Look forward to being educated.

Off to Stafford toy fair this Sunday will be with James Marshall on his stall when not looking, and John Knox.

Going to buy some poor quality models that do have variations under the casting to strip down to be kept as naked examples of differernt casting or that's my intention, plus looking for some trade boxes.

David

Regarding the subject of cross hatching on the underside of Dinky roofs and sometimes bonnets and boots. Prior to the mid 1960's the steel of diecast tools manufactured at Binns Road was not hardened. Over time the abrasive flow of Mazak damaged the top surface of the core that produces the inside of the models. This damage was sometimes called 'die soldering'. Rather than replace the core or totally remachine the damaged surface which would take time it was discovered by experiment that cross hatching disguised the damage and added less Mazak. During opreration it is the core of the tool that runs the hotest.

After discussion with tool steel manufacturers the steel quality of tools was changed and the tools were fully hardened. Tool life was now extended considerably and the need for cross hatching eliminated. An example of longevity is DT104 SPV the body tool of which produced approaching 250,000 shots before it had to replaced due to demand for the toy.

Meccano used Zinc Alloy type Mazak 3 which melts around 400C. During operation a diecast tool is water cooled to allow solidification of the Mazak after injection. Consequently the tool is subject to cyclical heating and cooling. This produces the effect of 'heat checking' which the steel quality has to resist and finally fails by crazing appearing on the die surfaces.

This caused the premature failure of the Avro Vulcan tool cast in Aluminium. The unhardened tool could not withstand the Aluminium at 600 plus degrees C.

Hope this helps with the discussion.

Vic Mumby (former Chief Draughtsman for products and tooling at Meccano Ltd)

Thank you Vic, that's fascinating information. I don't think the technical side of things is uppermost in many collectors' minds but a little understanding makes things much more interesting.

John

Vic--Thank you so much for further enlightening us on the apparent need and use of cross-hatching. It is a topic that has long promoted questions as to why it was used, and with no clear cut reason by anyone associated with Meccano. As I mentioned previoiusly, I was a young boy of around 13 when I first noticed it and became aware of the fact that some models had it and others did not. I am still interested in why the French Meccano factory used it so much earlier that the English factory. The French were utililyzing it around 1955-1956, based on obsverving several different models.

Best regards, Terry

That is the best education I have had on this subject, I bet you have many interesting technical facts you could recant.

David

Thank you all for the kind comments on diecasting. I would be pleased to try and answer any further questions either via the forum or private message. My time at Meccano covered 18 years from 1961 to 1979 starting as apprentice toolmaker and eventually becoming Chief Draughtsman.

Vic Mumby

Thank you, Vic, for this exclusive 'inside information'. It is a privilege for us to have you among our contributors and share such special experience and knowledge with us! Kind regards, Jan

Vic Mumby, I have so many potential questions difficult to know were to start.

1. do you know how many moulds were made for each model.

2. Have you any idea how many produced of each model.

3. Were models made in large batches or was it a more of a continious production.

Do you get to any collecting clubs especially near Preston UK.

David

Hello David,

1) Usually only one set of tools for each model. Exceptions would be if popularity of model demanded another tool due to tool wear, eg, DT104 SPV.

2) I have no knowledge of specific numbers for models, but the hardened tooling was designed to produce at least 100,000.

3) Production was scheduled to meet demand from sales, so run sizes would vary. Some models would be built for stock to cope with predicted Christmas demand.

Unfortunately I live in Hampshire close to Winchester so a bit far for club meets near Preston.

Vic Mumby

Interesting facts, does the 100,000 design rule apply to the earlier moulds in the 50's, 40's, and even the 30's. I assume that when the mould was too worn a new one was made, if the model was popular, but with slight changes presumably to ease casting. Is this correct?

Also slightly changing the subject, I have in my collection a 46 page typed booklet headed, MECCANO - AN EMPIRE FALLEN by Ronald C, Wyborn, in it he reminisces about various happenings during his working life at Binns Road, he apparently worked closely with the Hornby sons.. Did you know him?

David

I don't think tool life was consided before tool hardening was introduced in the 1960's. If a tool was damaged it would have been repaired, unless damaged beyond repair when it would be scrapped. A duplicate would only be made if the component was an essential part of another product or sales quantity showed it was worthwhile replacing.

I did meet Ronald Wyborn briefly after I joined the drawing office in 1965, but I think he left soon after for pastures new.

Vic

David T

This document must be very interesting and containing many interesting facts. What about publishing it at least privately ?

Jacques

David and Jacques,

Binns Road: An Empire Fallen by Ronald Wyborn has previously been published by the HRCA (Hornby Railway Collectors Association) as a suppliment of 23 pages to their 2010 December Journal. It may be subject to copyright so permission to reprint may have to be granted?

Vic

Thank you Vic, I think that I can borrow this copy of the excellent CAM Magazine.

Hopefully that article can either be shared or summarized for us. You would think it might have some very interesting information about Meccano and the Dinky Toys operation there!

Best regards, Terry

--40h and 254 Austin FX3 Taxi (1952-59)

-066 Bedford Flat Truck (1957-60)

-066 Bedford Flat Truck (1957-60)

--40h and 254 Austin FX3 Taxi (1952-59)

--40h and 254 Austin FX3 Taxi (1952-59)

--40h and 254 Austin FX3 Taxi (1952-59)

--40h and 254 Austin FX3 Taxi (1952-59)

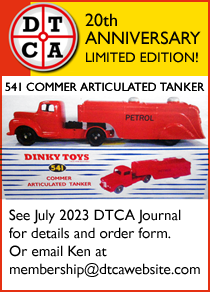

DTCAwebsite upgrade 2023

DTCAwebsite upgrade 2023

--30p and 440 Studebaker Petrol Tanker 'Mobilgas' (1952-61)

--30p and 440 Studebaker Petrol Tanker 'Mobilgas' (1952-61)

--30p and 440 Studebaker Petrol Tanker 'Mobilgas' (1952-61)

DTCAwebsite upgrade 2023

--30p and 440 Studebaker Petrol Tanker 'Mobilgas' (1952-61)

--30p and 440 Studebaker Petrol Tanker 'Mobilgas' (1952-61)

--30p and 440 Studebaker Petrol Tanker 'Mobilgas' (1952-61)

--30p and 440 Studebaker Petrol Tanker 'Mobilgas' (1952-61)

--30p and 440 Studebaker Petrol Tanker 'Mobilgas' (1952-61)

--30p and 440 Studebaker Petrol Tanker 'Mobilgas' (1952-61)

--30p and 440 Studebaker Petrol Tanker 'Mobilgas' (1952-61)

DTCAwebsite upgrade 2023

DTCAwebsite upgrade 2023

DTCAwebsite upgrade 2023

DTCAwebsite upgrade 2023

2024 AGM

2024 AGM

DTCAwebsite upgrade 2023

DTCAwebsite upgrade 2023

DTCAwebsite upgrade 2023

DTCAwebsite upgrade 2023

DTCAwebsite upgrade 2023

DTCAwebsite upgrade 2023

DTCAwebsite upgrade 2023

DTCAwebsite upgrade 2023

DTCAwebsite upgrade 2023